Misusing inferior stainless steel mixing bowls will lead to food flavor transfer, surface rust, and even the risk of regulatory inspection. As a professional stainless steel mixing bowl supplier, Billion Day is aware that safety issues are not just for operating costs but company image. In the following article, we will analyze the safety secrets of stainless steel mixing bowls to minimize your procurement issues.

What are Stainless Steel Mixing Bowls?

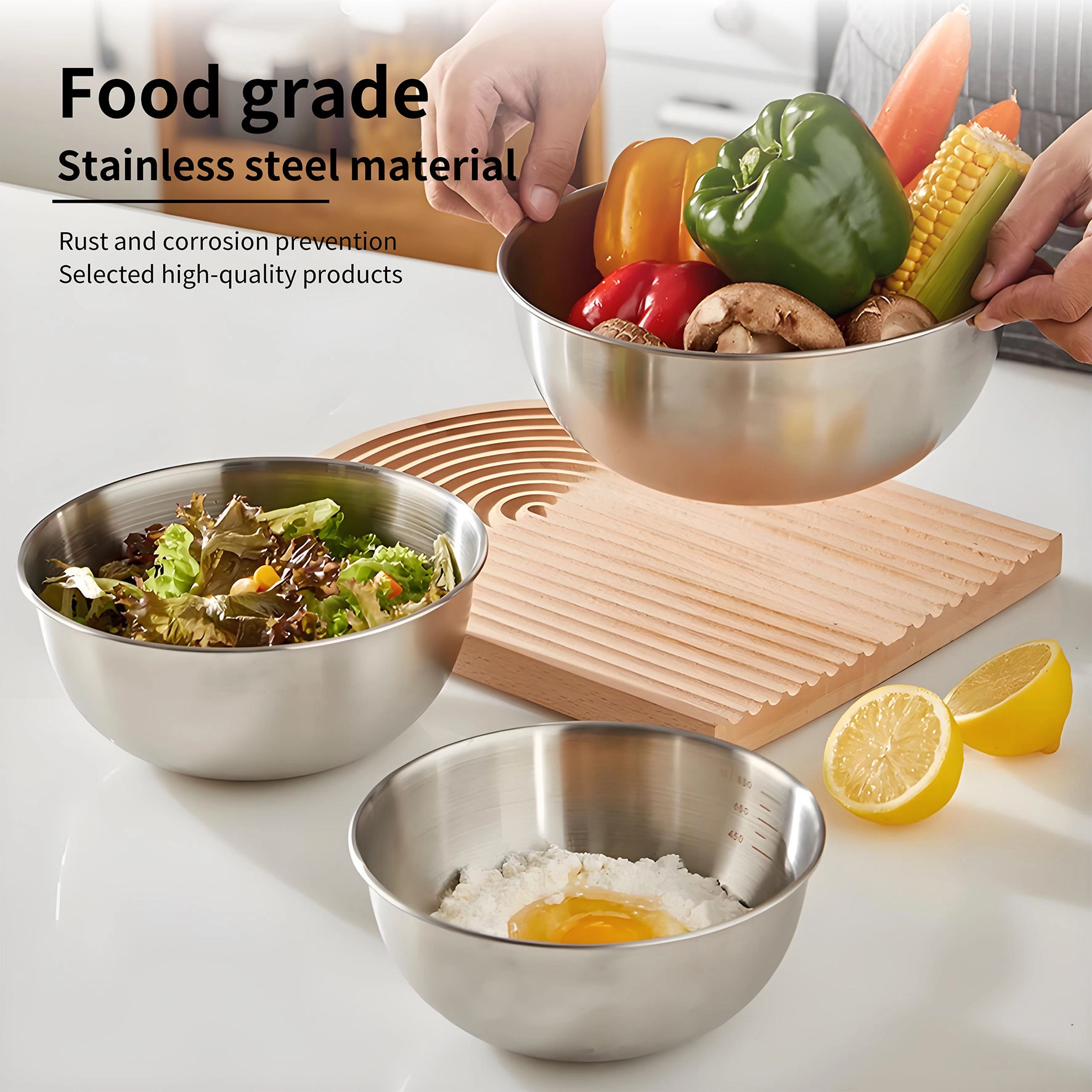

Stainless steel mixing bowls are used in the kitchen for food stirring and mixing. Typical materials include 201, 304, and 316 food-grade stainless steel.

Main applications:

- Hotel and restaurant kitchens: For tossing salads, marinating ingredients, and mixing sauces.

- Bakeries or bakery kitchens: For whipping egg whites, kneading dough, and beating batters.

- Central kitchens or food plants: For carrying out large-volume mixing operations.

- Buffets or caterings: To prepare food, season, or batch-process.

These applications require high safety, durability, and cleanability from the bowls.

Safety Analysis of Stainless Steel Mixing Bowls

The Importance of Food-Grade Stainless Steel

304 food-grade stainless steel does not release harmful chemicals and can be directly used on various types of food ingredients. Compared to ordinary metals or below-standard stainless steel, food-grade stainless steel is more corrosion-resistant, safer, and usable in the long term.

Stability in High Temperature and Acidic and Alkaline Environments

Stainless steel does not release poisonous chemicals when heated to extremely high temperatures or when exposed to acidic or alkaline food items. For example, 304 stainless steel remains stable in cooking tomato sauce, lemon salad, or marinating acidic food items.

Rust and Corrosion Resistance

Stainless steel is highly resistant to oxidation, rust, and moisture. It will never rust or discolor easily, even under damp kitchen environments after an extended period of usage.

Hygiene and Cleaning

Stainless steel possesses a smooth finish that is resistant to residue and can be simply washed with warm water and a neutral detergent, minimizing the possibility of bacterial growth.

International Standards and Certifications

High-quality stainless steel mixing bowls generally conform to food contact standards (e.g., FDA, EU Food Contact Directives, ISO, CE, etc.), providing business-to-business purchasers with peace of mind.

Comparison of Mixing Bowls of Various Materials

| Material | Advantages | Disadvantages | Ideal Applications |

|---|---|---|---|

| Stainless Steel | Durable, resistant to corrosion, easy to clean, food-grade | Opaque, no transparency | Commercial food preparation, restaurants, hotels, central kitchens |

| Glass | Clear, good transparency | Fragile, poor heat conductor | Baking, visual presentation |

| Plastic | Lightweight, cheap | Risk of BPA content, easily scratched, heat-resistance | Home use, low-cost catering |

| Ceramic / Enamel | Colorful | Fragile, heavy | Up-market catering, visual presentation |

Stainless steel mixing bowls outclass other materials in durability, safety, and cleanliness and are the preferred option for commercial food preparation.

Best Practices for Use and Care of Stainless Steel Mixing Bowls

- Avoid scratching the bowl surface with metal scrapers.

- Avoid storing strong acids or salt water in the bowl for prolonged periods.

- Clean in warm water and a neutral detergent; avoid using abrasive steel wool.

- Be cautious to avoid burns when high-temperature sterilizing.

- Regularly inspect welds, seams, and bowl bottoms for corrosion and scratches

- Attention to use and care can extend the lifespan of your bowl while ensuring food safety.

Tips on Purchasing Safe Stainless Steel Mixing Bowls

- Wholesale Supply: Choose a supplier with a consistent supply and adequate inventory.

- Look at Customization Capabilities: Customize sizes, thicknesses, and logos to suit your restaurant’s needs.

- Sample Testing: Conduct high-temperature, acid/alkali, and cleaning tests first.

- Material Certification: Inspect food-grade certifications, test reports, and vendor qualifications.

- Cost vs. Lifespan: Weigh the initial cost of purchase against the long-term benefits of longevity.

Choosing a reliable manufacturer like Billion Day offers one-stop service and a bulk purchase advantage.

Conclusion

Due to their compliance with food safety regulations, durability, cleanability, and low cost, stainless steel mixing bowls easily meet the demands for use in a commercial kitchen over the long term. There are different sizes and types of mixing bowls and ensuring you choose the correct size, and maybe even type, will help you have all the bowls and components for your kitchen. Contact us for custom high-quality stainless steel mixing bowls to facilitate efficient operations in restaurants, hotels, and central kitchens.